Listening

to meet

your needs

Air System Evaluation

Flow meters for compressed air

The importance of measuring flow in a compressed air system

Save money, improve efficiency and be worry-free by measuring and monitoring your compressed air. Pneumatic machines wear out. Systems are often oversized, consuming more energy than necessary. With continuous monitoring, you can anticipate problems and ensure that the compressed air system is always available for your business needs.

Compressed air flow meters show you where, when and how much air is being used. You'll know where leaks are and how much waste they cause. Use real data to justify improvement investments and maintenance management and generate energy savings.

VPFlowscope M Flowmeter

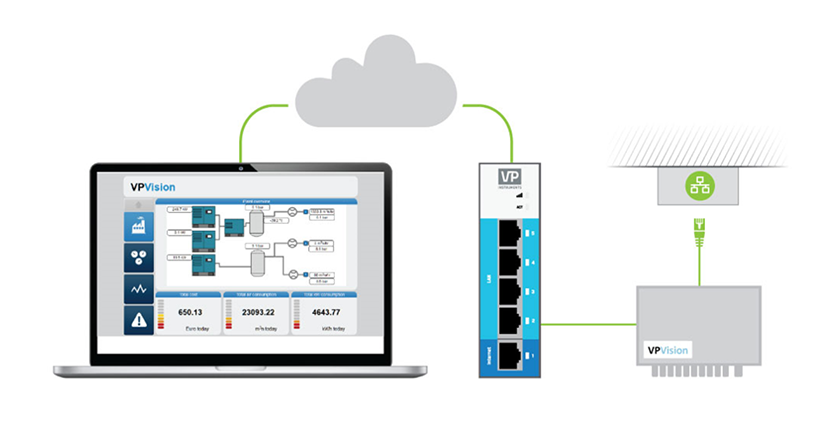

This new generation flowmeter is ready for Industry 4.0 / IOT Industrial Internet of Things

The ultimate tool for measuring saturated compressed air, even hot air.

It also has a built-in Ethernet (Modbus/TCP) interface, which facilitates direct connection to any network. It can be installed under pressure and simultaneously measures (bidirectionally) thermal mass flow, pressure, temperature and total flow.

This differential pressure flow sensor measures the bi-directional flow of pressure, temperature and total flow simultaneously.

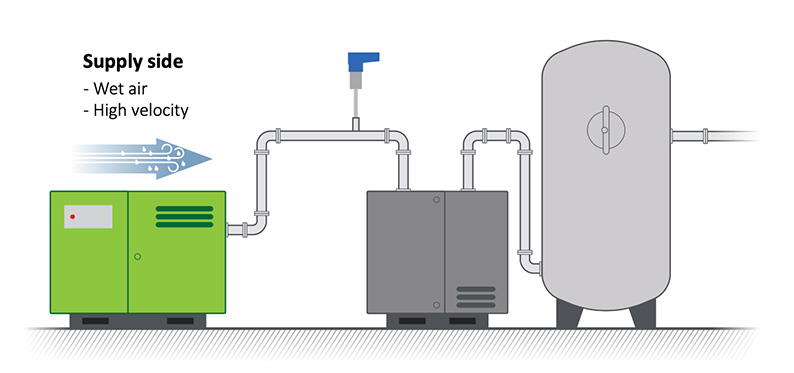

Its unique design allows you to make measurements in the discharge pipe of any compressor under 100% saturated conditions.

You can measure the performance or efficiency of your compressor. In addition, you can measure the compressor's contribution to the total compressed air supply.

Managing your cookies

The Internet is based on a number of fundamental principles and technologies. Above all, the exchange of data is its very essence.

Without this exchange, there is no network, and therefore no Internet.

Managing your user experience through cookie management

Your personal information is valuable, and it's up to you to decide which information you wish to share with us. You can use the links below to enable or disable certain browser cookies. Cookies that are essential to the proper functioning of certain sections of our digital content cannot be disabled.

Configurations on our website designed to simplify your browsing will not work if you use tools to block cookies.

Disabling cookies

Most browsers allow you to manage the cookies stored on your computer. Please refer to your browser's instructions for disabling cookies on your device.

Visit the page corresponding to the browser you are using to find out more:

If your browser is not listed above, please visit its website.

Strictly necessary cookies

Necessary cookies are essential for the basic functionality of the website. Without them, our site would not function as intended. These cookies do not store any data that could be used to identify an individual user.

Functionality cookies

They help the site to remember certain data about your visit, which may both facilitate your subsequent visits and make our site more useful to you.

Performance cookies

These cookies collect information about your use of our website. For example, which pages you visit most often. This data can be used to optimize our website and make it easier to navigate.

Targeting and social media cookies

You need these cookies to see personalized pages or ads that are more likely to interest you, or to avoid seeing the same content over and over again. These cookies are used to present you with relevant advertising. They also limit the number of times you see an ad and help us measure the effectiveness of our marketing campaigns. We may share this information with other parties, including service providers, social media partners and ad management solutions.

Analytics cookies

These cookies (provided by Google Analytics) enable our site to track the number of visits and sources of traffic so that we can evaluate and improve the performance of our site.

We use cookies to improve your experience with our digital content and for advertising purposes. Your privacy is important to us. If you are uncomfortable with our use of the information we collect, please review your browser settings before continuing your visit. Any further use of this site will be considered as consent.

Chat with us

Chat with us

Question / Comments ?

Question / Comments ?